Entering the factory / When working in confined spaces, electric air supply long tube respirators are preferred

Release time:

Aug 05,2024

In early January, technicians from Jingzhou Strong company were invited to conduct hazardous substance testing at a chemical plant and developed respiratory protection plans based on the test results.

In early January, technicians from Jingzhou Strong company were invited to conduct hazardous substance testing at a chemical plant and developed respiratory protection plans based on the test results. The on-site working environment is a deep tank with a diameter of 2 meters and a height of 6 meters, and the top inlet diameter is only 90 centimeters.

On site workers are wearing half face masks to perform cleaning and maintenance operations inside the tank.

After using a gas analyzer for detection, technicians found that the main gas inside the tank was organic gas, which was significantly irritating to the skin and eyes with a hazard factor of 9. The oxygen concentration at the bottom of the tank was only 18%. This test result indicates that the half face mask protection scheme originally used by the workers had significant safety hazards.

The main hazards of working in confined spaces

1.Hazards of hypoxia

Due to the limited space and inconvenient operation, it will invisibly increase the labor intensity of the workers, thereby accelerating the oxygen consumption rate and making them prone to hypoxia. If adequate ventilation and oxygen supply are not provided, workers are prone to coma due to lack of oxygen, and in severe cases, even death may occur.

2.Toxic and harmful gas hazards

The working environment of small spaces combined with harmful gases makes it difficult for gases to diffuse and easily leads to the accumulation of toxic and harmful gases, increasing the concentration of harmful gases and posing a risk of poisoning.

How to do respiratory protection well in confined space operations?

1.Wear respiratory protective equipment

Select appropriate respiratory protective equipment, such as dust masks, gas masks, etc., based on the types of harmful substances and hazard factors in the work environment.Ensure that respiratory protective equipment complies with relevant standards and regulations, and can effectively filter harmful substances in the air.

2.Regular inspection and maintenance

Regularly check the filtering elements and sealing performance of respiratory protective equipment to ensure their normal operation. If damaged or expired, it should be replaced in a timely manner. At the same time, pay attention to cleaning and maintaining respiratory protective equipment to extend its service life.

3.Maintain ventilation

When working in confined spaces, good ventilation should be maintained to minimize the accumulation of harmful substances. If possible, ventilation equipment or mechanical air supply can be used to enhance air circulation.

Jingzhou Strong company recommends electric air supply long tube respirators as the preferred choice for working in confined spaces.

1.Continuous air supply ensures safety

Dual power supply of alternating current and battery, avoiding protection failure caused by temporary power outages, continuously providing fresh air, ensuring smooth breathing of workers, and reducing the risk of hypoxia or poor breathing.

2.Flexible long-distance air supply operation

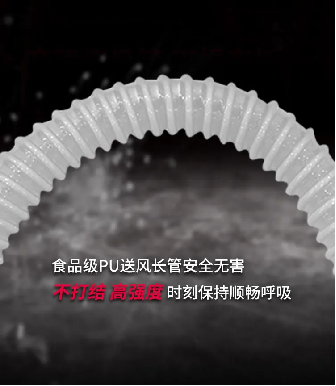

The maximum conveying distance is 80 meters, and the high-strength PU air duct is resistant to bending, making it easy for operators to move when working in narrow spaces.

3.Strong adaptability, suitable for multiple scenarios

Suitable for working environments in various narrow spaces, such as pipelines, containers, basements, etc. It has good ventilation effect and can provide sufficient oxygen supply, allowing workers to breathe smoothly and reducing the risk caused by enclosed environment.

keywords

Latest News

On July 30th, Jingzhou Strong held its 2024 Dealer Conference in Jingzhou city, Hubei Province, More than 180 dealer representatives from all over the country gathered together to seek common development.

Aug 05,2024

SAF Coolest v1.3.1.2 设置面板 GAGSD-ZGYF-JFSFE-ZSE

无数据提示

Sorry, the current column is being updated, please stay tuned!

You can view other sections or go back Home page